●RAW MATERIAL TESTING

Check the documents: each batch of incoming materials shall check the name, specification and mark of the goods according to the delivery note;

Specification: the weight difference of each alloy ingot should be within 10%;

Chemical composition: check according to the chemical report provided by the raw material supplier;

HSFverify the validity of SGS report (1 year);

Packaging: the product shall be packaged in the same way and in good condition;The quantity and weight meet the requirements of the delivery note;

●ALUMINUM INGOTS MELT AND SLAG EXHAUST

Large inert gas bubbles are broken into very fine bubbles by rotors that rotate at high speeds and spray inert gas and granular fluxes, and are evenly dispersed throughout the liquid metal.By reducing the bubble diameter, the total surface area of these bubbles increases dramatically, allowing more inert bubble surfaces to come into contact with the hydrogen and impurities in the liquid metal and bring these harmful substances to the surface of the liquid.

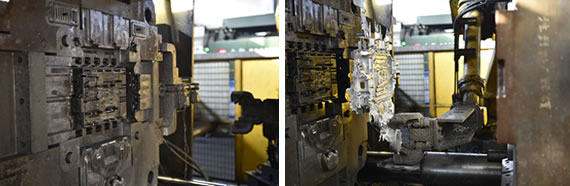

●DIE CASTING MOLD

There are 8 Hong Kong dynamic die-casting machines with a total capacity of 400-2000 tons in the die casting test workshop, which can meet the requirements of different sizes of die casting.

●DIE CASTING MASS PRODUCTION

Try die-casting mould workshop, 400-2000 tons of Hong Kong force strength die-casting machine 8 units, cooperate with the die casting machine peripheral automatically to take soup robots, robot spraying system, robot a embedded system, die casting sprue cutting device, yard printing machine for die casting, quick die change system, product conveying equipment, intelligent CNC processing a variety of automation equipment, such as casting production requirements.